29 June 2021

The Opportunity For Sustainable Fuels In Motorsport Applications

In another of our series exploring the potential benefits of sustainable fuels, we’re putting a spotlight on the World Rally Championship (WRC).

At Coryton, we’ve been busy developing a range of second-generation advanced bio-gasolines derived from agricultural waste. Here we’ll explore the work undertaken in partnership with M-Sport to quantify the impacts on combustion of a drop-in, high bio-content gasoline in a current World Rally Championship (WRC) engine compared to a conventional fossil fuel.

This serves to show how these fuels could be used as partial (in the form of blending) or direct replacements for fossil fuels to reduce the greenhouse gas (GHG) emissions from road transport, with minimum impact on the consumer.

The Sustainable Fuels

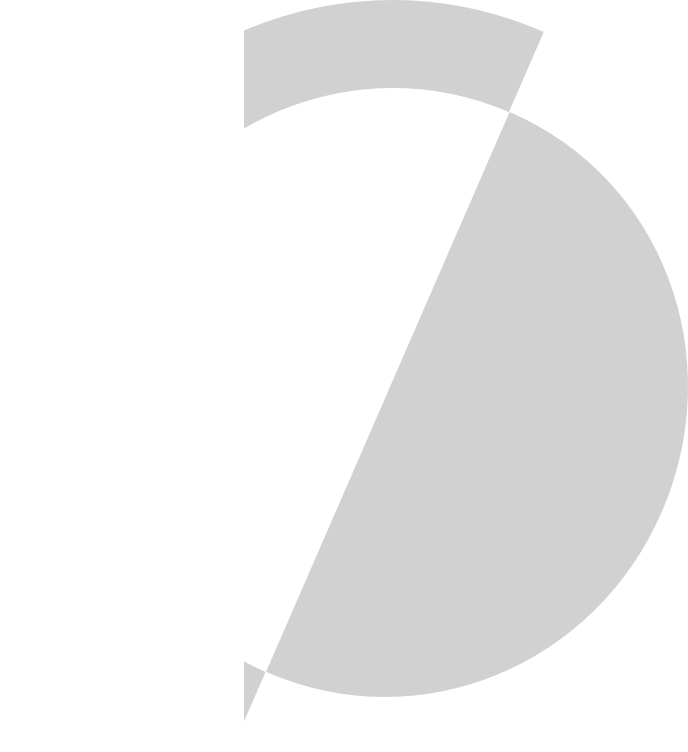

The sustainable gasoline used in this study has been described in more detail in this article and is produced in two main stages. The first stage is to generate bioethanol from waste biomass; in our case this was agricultural waste such as straw. This bioethanol can then either be:

1). Added directly to a gasoline to create an ethanol blend e.g. E10 – 10% v/v ethanol; or

2). Further processed into bio-gasoline as shown in Figure 1 below in order to increase the bio-content of the final fuel well beyond the pure bio-ethanol blend wall

In this study, a bio-gasoline was designed and created by our specialist fuel formulators and compared to a fossil gasoline of similar RON and MON characteristics.

| Property | Test fuel specifications | |

|---|---|---|

| Fuel 1 (bio) | Fuel 2 (conventional) | |

| Total Bio-Content (%) | 97* | 0 |

| Alcohol Content (% v/v) | 20 | 0 |

| RON | 100.8 | 100 |

| MON | 87.2 | 87.2 |

| Aromatics Level (% v/v) | 33.6 | 33.3 |

| GHG Savings (RED II) (%, basis 94.0g CO2e/MJ) | 82.8 | 0 |

As can be seen from the table above, by increasing the ethanol level and retaining low concentrations of fossil material, it was possible to match or exceed the physical properties of the conventional fossil gasoline. Sustainable versions of the remaining fossil components are currently in development and will be available in the near future, enabling 100% sustainable content and further improving the GHG savings afforded.

*A fully sustainable version of this fuel will be achievable in the near future

The Engine

The fuels were tested on a current WRC engine, specifications for which are given below:

| Property | Value |

|---|---|

| Capacity | 1.6 litre |

| Cylinders/Valves | 4/16 |

| Bore x stroke (mm) | 83 x 73.9 |

| No. of cylinders | 4 |

| Compression ratio | 12.5:1 |

| Aspiration/injection technology | Turbocharged DI |

The Test Points

The engine performed a full-load power curves with ignition timing and lambda optimised for each fuel. For a fair comparison between the fuels, the following tests were performed:

| ID | Fuel | Calibration |

|---|---|---|

| Test 1 | Fuel 2 | Optimised for Fuel 2 (Baseline) |

| Test 2 | Fuel 1 | Optimised for Fuel 2 |

| Test 3 | Fuel 1 | Optimised for Fuel 1 |

In the following charts, “baseline” calibration refers to “Optimised for Fuel 2” in the table above.

Results and Discussion

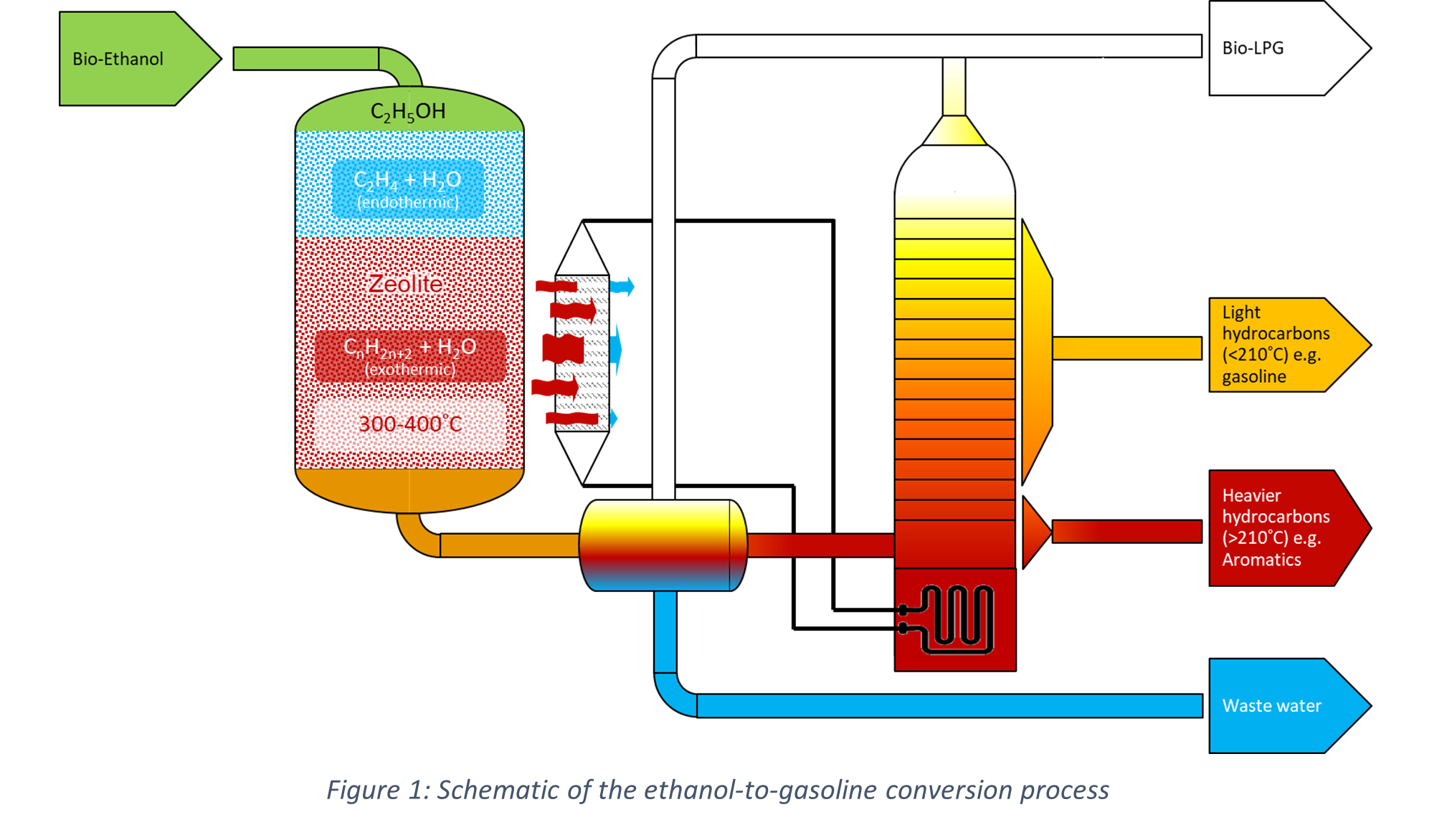

Full-load power and torque against engine speed are presented for both fuels at fixed lambda, but with both optimised and baseline ignition timing.

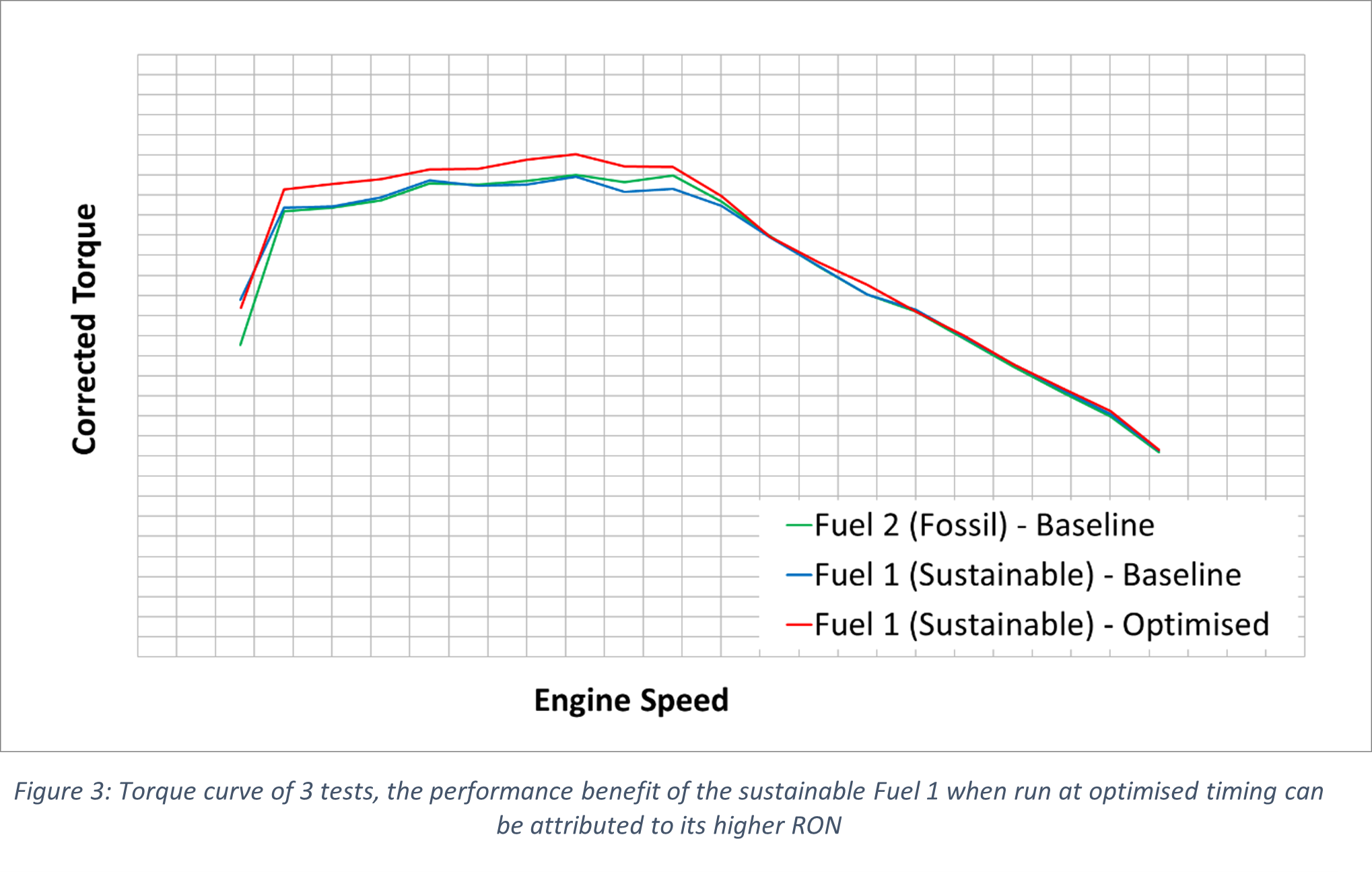

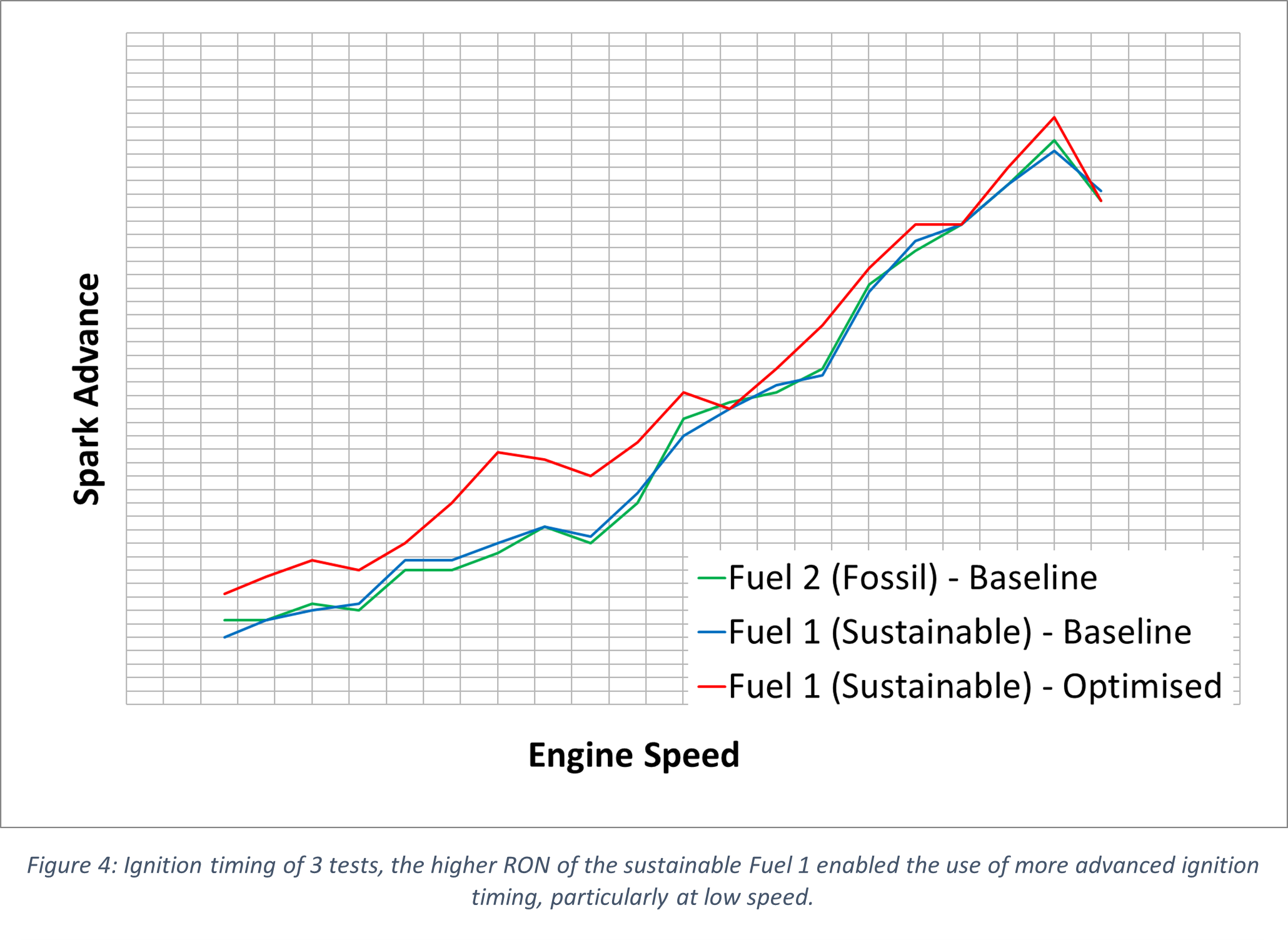

While the sustainable fuel demonstrates an improvement in power and torque (Figures 2 and 3) when tested with optimised ignition timing (Test 3), we can see that no significant performance difference exists when both fuels are tested with the same calibration settings (Tests 1 and 2). These results suggest that the performance benefit can be attributed directly to the optimised calibration, driven by the slightly higher RON of the sustainable fuel rather than any other properties of the fuel.

Figure 4 highlights the difference in spark advance enabled by the slightly higher RON value of the sustainable fuel under optimised calibration (Test 3), particularly noticeable at lower engine speeds where knock is more pronounced. This increase in spark advance translates into an improvement in efficiency and therefore power and torque for the sustainable fuel.

Our Final Thoughts

The work carried out by our team on this trial demonstrates the potential for sustainable fuels to be used within WRC and other high-level motorsport applications, all without experiencing any drop in performance relative to conventional fossil fuels but with a significant reduction in greenhouse gas emissions.

In this study, the performance differences experienced between a sustainable fuel and its fossil predecessor could be easily explained by their relative octane quality. While the bio-gasoline tested already demonstrated a significant improvement in GHG emissions, this will continue to improve over time as the availability of more high-performance sustainable fuel components continues to widen.

Contact us today if you’re interested in finding out more about how we can help your motorsport series quickly improve its carbon footprint.