27 May 2021

The Opportunity For Sustainable Fuels In High-Performance Engines

We must embrace all available technologies if we are to make a real impact on reducing the greenhouse gas emissions from transport. While we strive towards electrification, we must not forget about all the existing internal combustion engined vehicles on the road, including all those that will be sold between now and any phase out dates.

We must also not forget about the sectors that are harder to electrify such has heavy goods vehicles and aviation. Unlike electric and fuel-cell vehicles, sustainable fuels offer an opportunity to address these issues while we transition to new forms of mobility.

At Coryton, we have been developing a range of second-generation advanced bio-gasolines, derived from agricultural waste, that conform to the EN228 specification. On this particular project we partnered with Cosworth to demonstrate the drop-in nature of various bio-gasolines, by characterizing the combustion effects of high bio-content EN228 gasoline fuels in two different engines.

The results serve to illustrate how these fuels could be used as partial (in the form of blending) or direct replacements for fossil fuels to reduce the greenhouse gas (GHG) emissions from road transport with minimum impact on the consumer.

The Sustainable Fuels & Processes Involved

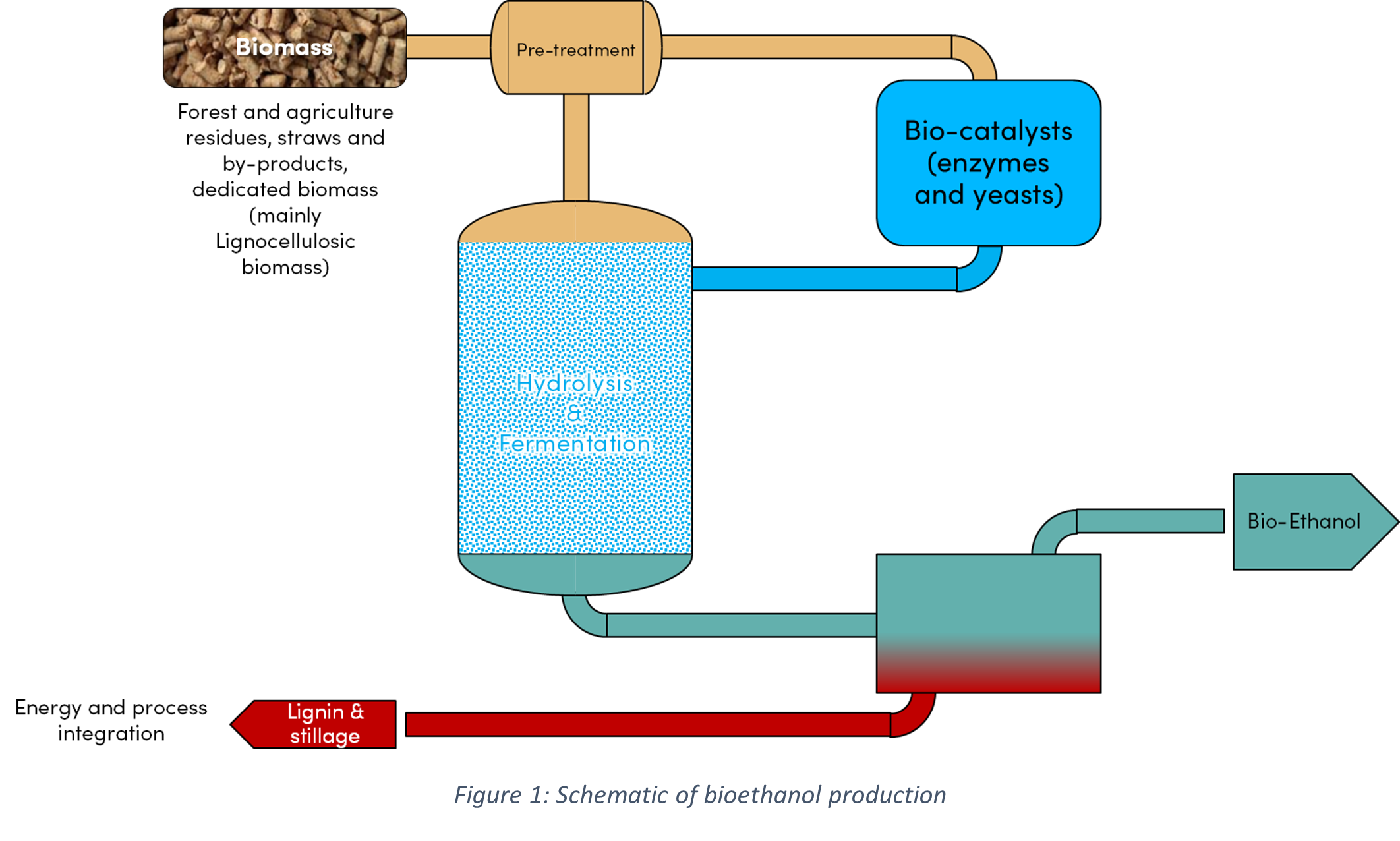

The sustainable gasolines used in this study are produced in two main stages. The first stage is to generate bio-ethanol from waste biomass; in our case this was agricultural waste such as straw. First, this lignocellulosic biomass is pretreated to improve the accessibility of enzymes. After pre-treatment, the biomass undergoes enzymatic hydrolysis for conversion into sugars which are then fermented to ethanol by the use of various microorganisms (Figure 1).

This bio-ethanol can then either be:

- Added directly to a fossil-based gasoline in blends of up to 5 or 10% (E5 or E10) dependent on the territory

- Further processed into bio-gasoline in order to increase the bio-content of the final fuel well beyond the pure bio-ethanol blend wall

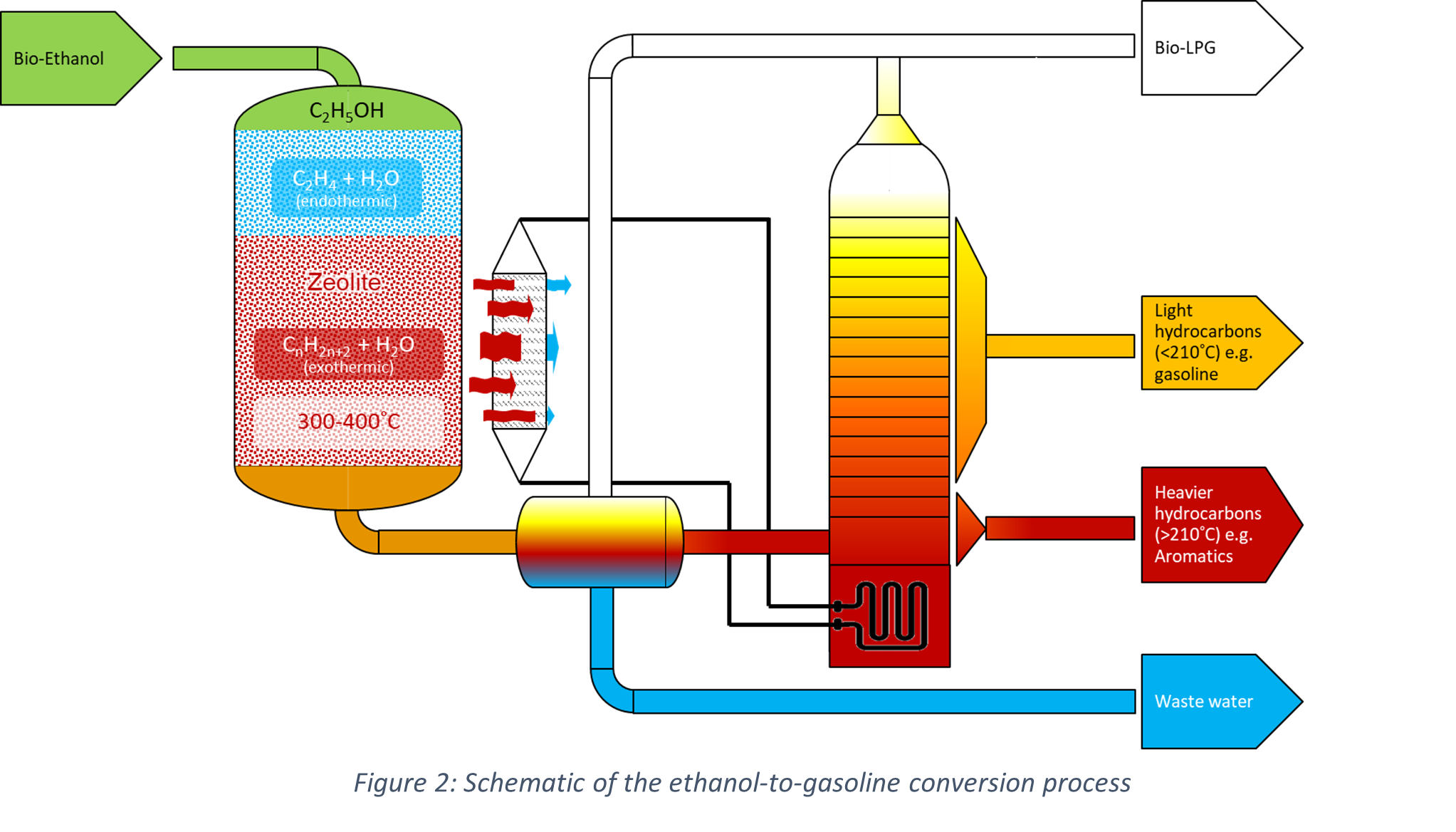

For the further processing into bio-gasoline, the bio-ethanol is first dehydrated into ethylene and then “grown” into longer chain hydrocarbons in the presence of a zeolite catalyst at ~300-400°C. The raw bio-gasoline requires blending in order to comply with the EN228 specifications.

In this study, 3 different bio-gasolines were blended as shown in the table below.

As can be seen, that variation in the requirements for octane and maximum ethanol content can require the use of some fossil components in order to meet the specification, but it is expected that bio or synthetic versions of these components will become available and further improvement in GHG savings can be expected.

| Property | EN228 drop-in bio-gasoline fuel specifications | ||

|---|---|---|---|

| 95RON E5 | 98RON E5 | 98RON E10 | |

| Total Bio-Content (%) | 88.8 | 71.8 | 73.5 |

| Alcohol Content (% v/v) | 5 | 5 | 10 |

| RON | 95.4 | 97.7 | 99.0 |

| MON | 85.2 | 86.5 | 85.3 |

| Net Cal. Value (MJ/kg) | 42.0 | 41.9 | 41.3 |

| Aromatics Level (% v/v) | 34.5 | 34.6 | 24.5 |

| GHG Savings (RED II) (%, basis 94.0g CO2e/MJ) | ~80 | ~65 | ~66 |

The Engines Used in the Testing Phase

Two high performance engines were selected for this study: one a boosted direct injection engine, the other a high speed naturally aspirated, port fuel injected engine.

| 2.3 litre Ford Ecoboost development engine | 1.0 litre 12,000rev/min development engine | |

|---|---|---|

| Bore x stroke (mm) | 87.6 x 94 | 81.5 x 63.8 |

| No. of cylinders | 4 | 3 |

| Compression ratio | 9:1 | 14:1 |

| Aspiration/injection technology | Turbocharged DI | NA PFI |

Both engines were run with the Cosworth engine management system (EMS), with manually optimised control settings at each test point.

The Key Test Points

A number of operating points were run on each engine for each fuel as follows and as illustrated in Figure 3:

- Standard world-wide reference points:

- 2000 rev/min/2.00 bar

- 1500 rev/min/2.62 bar

- WLTC representative points

- Mid-map point for minimum BSFC

- Full load corner points

- High-speed points

The Results

A number of key combustion and efficiency characteristics were measured for each fuel and engine.

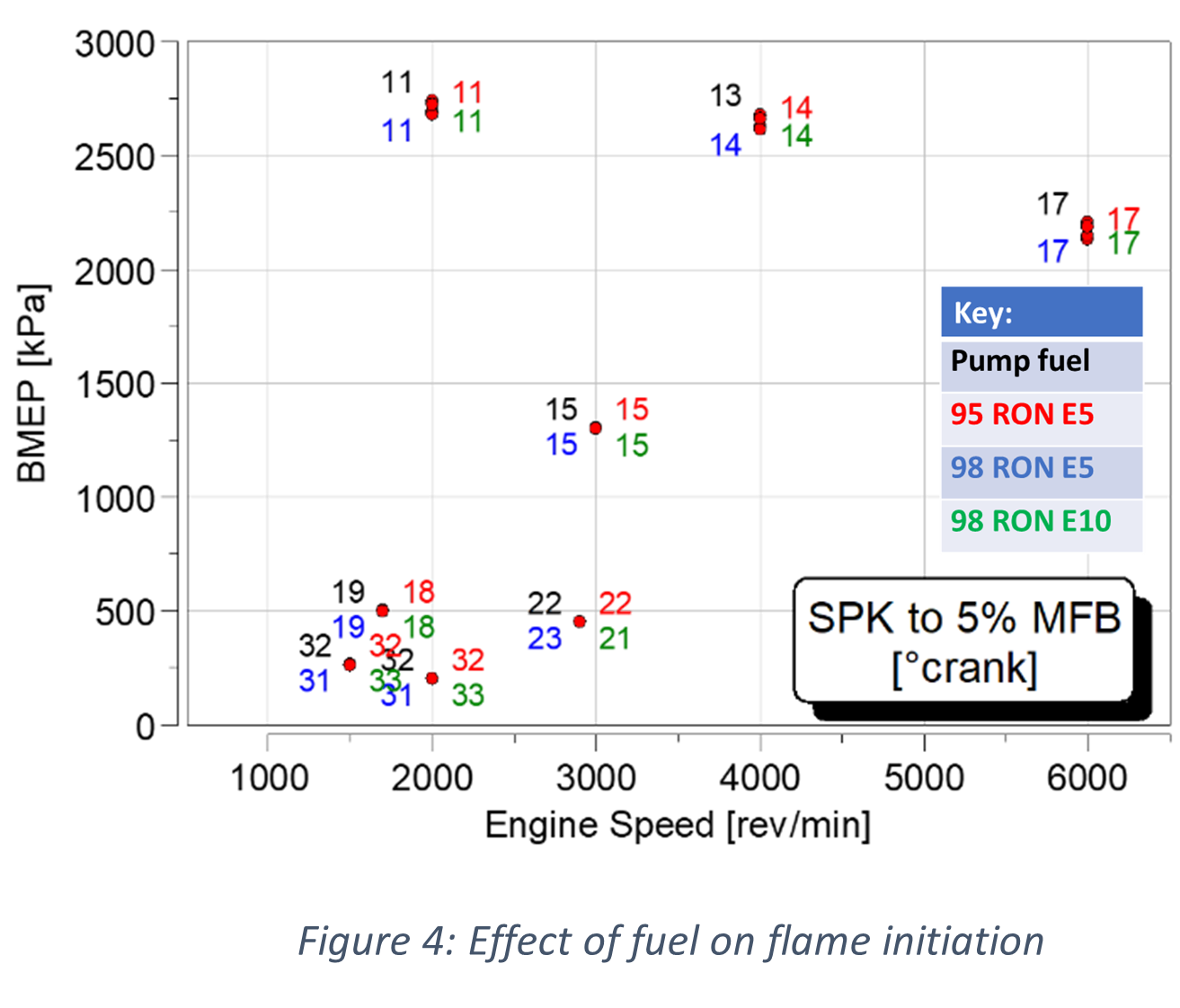

Figure 4 shows that the impact on flame initiation, as measured by the time of spark to 5% mass fraction burnt (MFB) in crank angle degrees, is negligible.

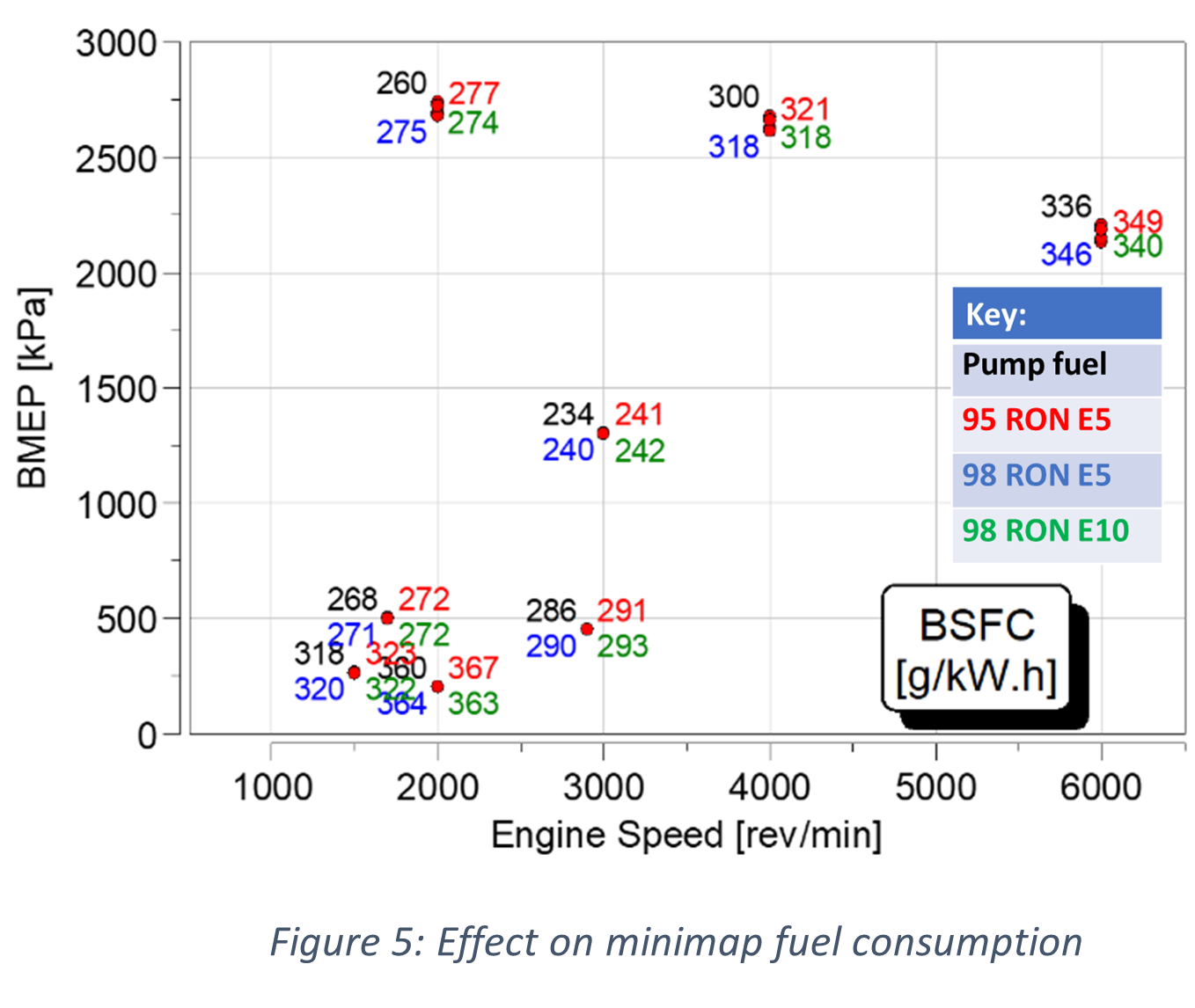

Similarly, while there are some small differences, the effect on the minimap fuel consumption figures is small (Figure 5).

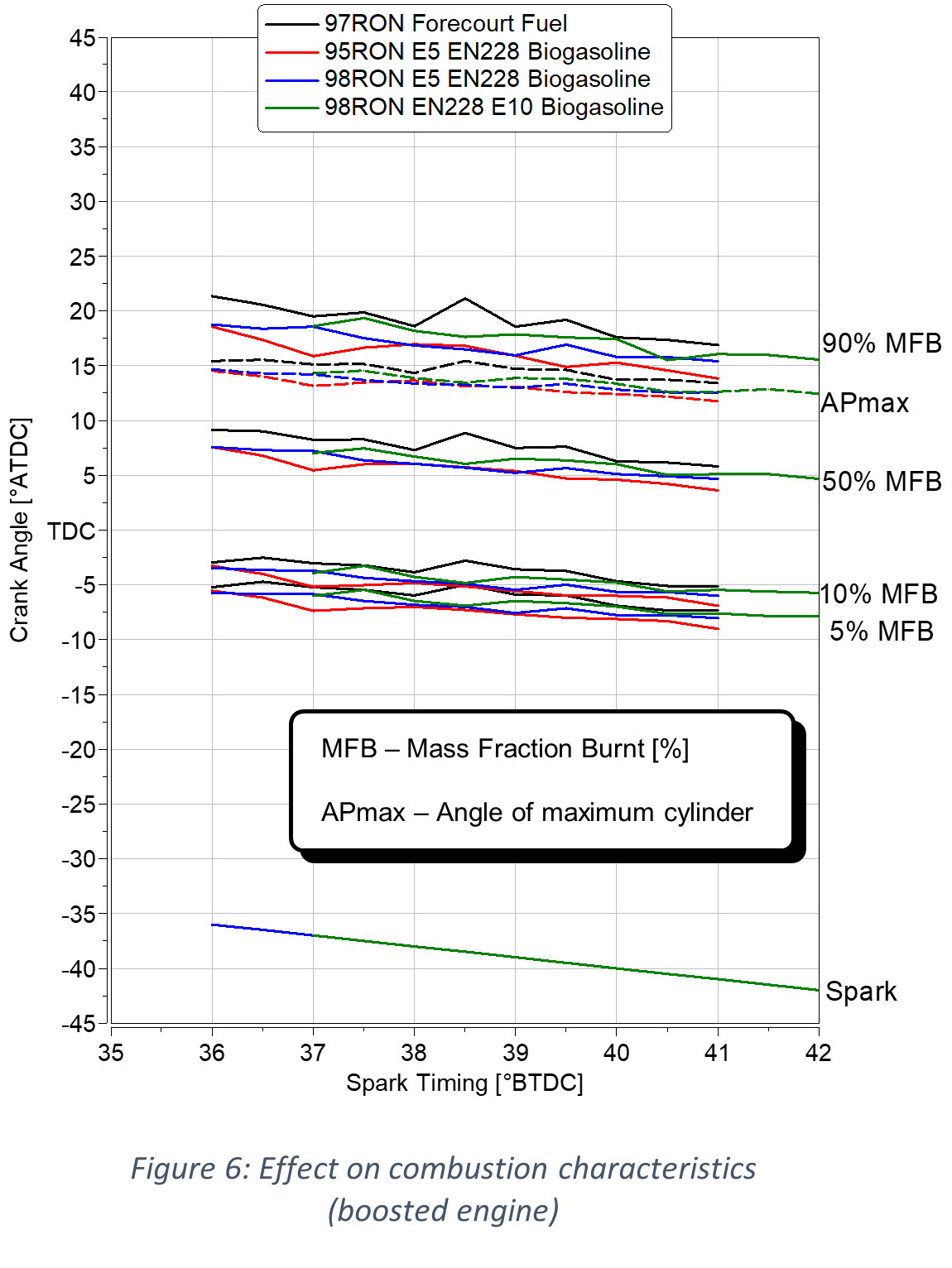

At the 2000 rev/min, 200kPa (2 bar) BMEP operating point the boosted DI engine showed that the E5 biofuels tended to burn a little faster than the pump grade fuel tested (despite what is assumed to be a higher aromatic content) possibly influenced by flash boiling of the alcohol content (Figure 6). The E10 fuel showed slightly slower burning characteristics, bringing combustion closer to the pump grade fuel tested (despite a lower aromatic content).

However, the differences seen only amounted to 1 to 2° on 10-90% burn times and are within the range typically seen with varying EN228 fuels, especially considering alcohol content.

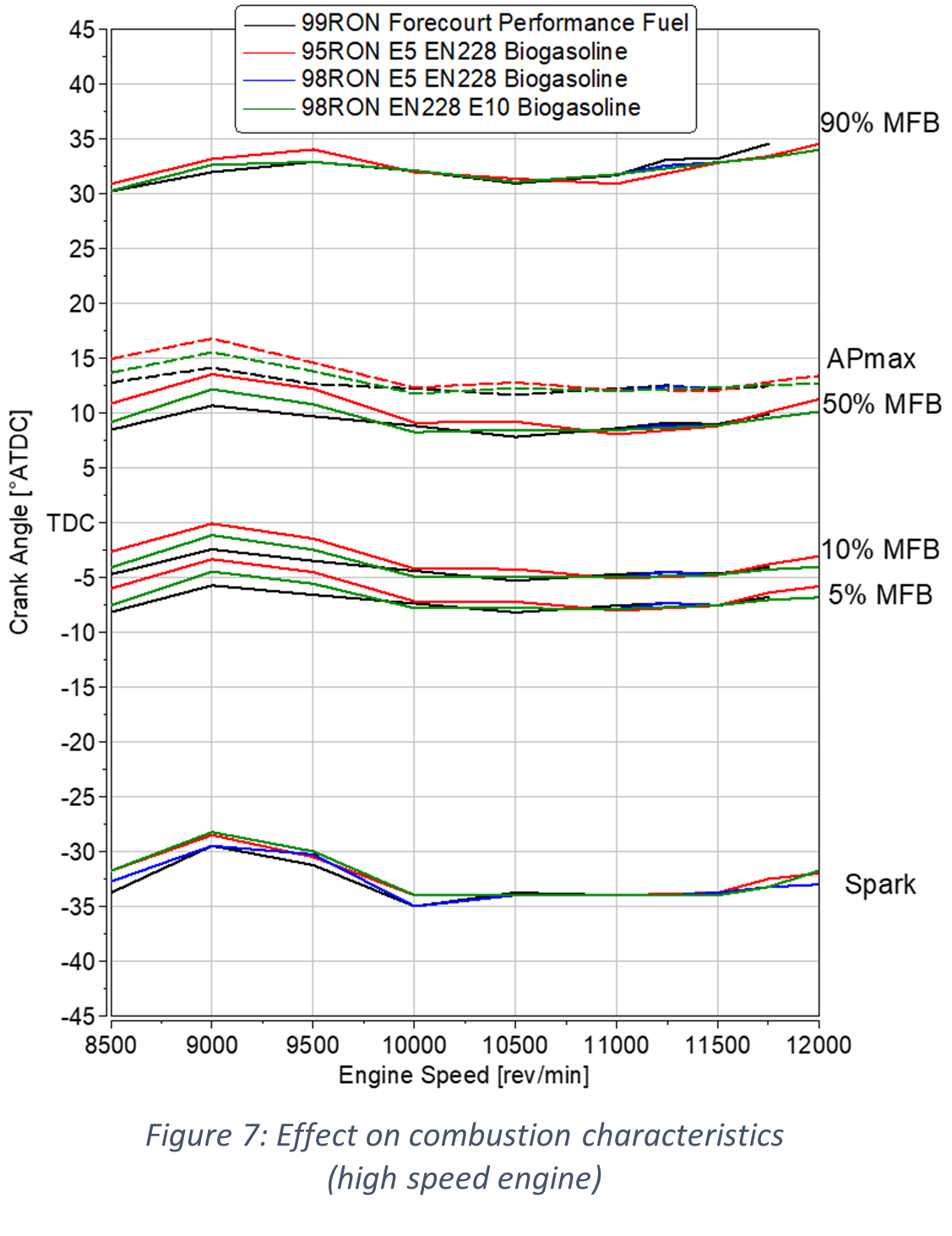

For the high-speed engine application, knock response below 9,500 rev/min related more °, closely to MON than RON values but, above this speed, the engine was not knock limited on any of the fuels tested (Figure 7). Under these conditions, there was very little difference in the combustion profile between any of the fuels tested.

Our Final Thoughts

The main focus of this collaborative work with Cosworth was to demonstrate the drop-in opportunity for advanced bio-gasolines. Although there were some subtle differences seen in the combustion characteristics between the EN228 bio-gasolines and the current pump grade fuels, these were well within the range of characteristics found in the various different fuels available on the forecourt.

Beyond these generic qualities, no fundamental differences in engine operation were observed and so from the results, there is very good potential for the low GHG EN228 biofuels to be used as a direct replacement in IC engines without any re-calibration required.

Each of the bio-gasolines tested significantly reduce the GHG emissions, and these savings could be improved further in the future. The ethanol-to-gasoline process enables a significantly increased bio-content beyond that allowed for bio-ethanol on its own (E5 or E10). For example, it would be perfectly feasible to offer a 95RON E10 fuel (already available as a fossil-based pump fuel in many European countries and available in the UK from September 2021) with 100% 2nd generation bio-content enabling a potential 90% savings in GHG emissions on a RED II basis.

Practically, these fuels are currently relatively expensive and not available in sufficient quantities for an immediate full and direct replacement, and investment is required in order to improve process efficiencies and economics.

However, it does not need to be an all-or-nothing switch. Blending these bio-gasolines into existing fossil-based fuels would offer a managed transition to increasing the sustainable component in EN228 fuels available on the forecourt, thereby reducing the GHG emissions of the existing fleet as well as vehicles sold in the future with ICEs.